De-Risking New Service Provider Technology Deployments – Benefits of a Unified Tool Rail

How a unified tool rail helps to de-risk the deployment of the new Triple Challenge technologies

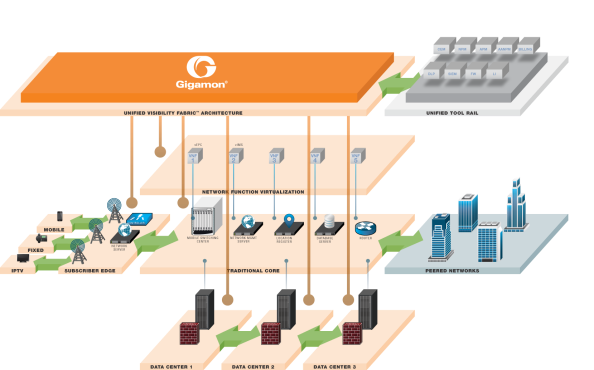

In the below diagram, we can see how a unified tool rail that has visibility to each new technology and to all the places in the network where issues could be come apparent will allow operators to be able to de-risk the deployment of the new Triple Challenge technologies in a predictable and systematic way.

The unified tool rail shown in the diagram is superimposed on top of the Gigamon Unified Visibility Fabric™ architecture which sits on top of the network itself. All parts of the network are being monitored in unison, allowing the following to be understood and analyzed:

- How each of the Triple Challenge technology deployments affects the other technologies

- How each transported traffic type is affected by each deployed technology

- How RTP traffic is affected by other transported traffic types

The diagram also includes the new NFV layer and the more traditional virtualized data center layer. This allows the operator to understand if there are interactions between the user-generated East/West traffic and possible interactions with the North/South virtual transport traffic. Spot solutions, or “thin layer monitoring solutions” from existing router and switch manufacturers simply do not have either the pervasive visibility—for example no ability to monitor virtual networks, nor the rich feature set to be able to make sense of the monitored data. Therefore they do not possess the ability to provide insight on the complexities associated with the deployment of Triple Challenge technologies. The advantage of a unified tool rail and the Gigamon Unified Visibility Fabric architecture is the ability to gain visibility across the new technologies eliminating any barriers or silos.

Conclusion

In the figure above, it can be seen that each of the three new technologies is being comprehensively monitored, such that the impact of one upon another is minimized, facilitating the prompt understanding of the unknown or misunderstood interdependencies. When looking for the “needle in the haystack,” end-to-end visibility changes the dynamic of monitoring. This allows an operator to not only reduce the size of the haystack, but facilitates looking at the correct haystack and more importantly for the correct needle, avoiding false positives. Overall the ability of the monitoring system, the Unified Visibility Fabric architecture, and the unified tool rail can enable the operator to de-risk the deployment of new technologies, maintain network uptime, deploy technologies faster with the same amount of resources, reduce network and service down time, reduce customer support service call costs and ultimately reduce churn.